There are two basic configuration types of Flue Duct Expansion Joints: belt and flanged. Both types can be round or rectangular.

See by type

-

Belt Type

-

Flanged Type

APPLICATION EXAMPLES

There are two basic configuration types of Flue Duct Expansion Joints: belt and flanged. Both types can be round or rectangular.

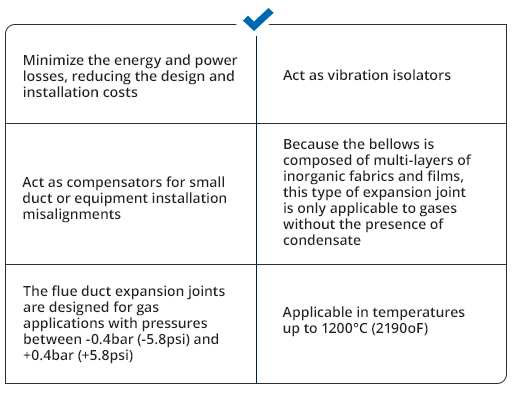

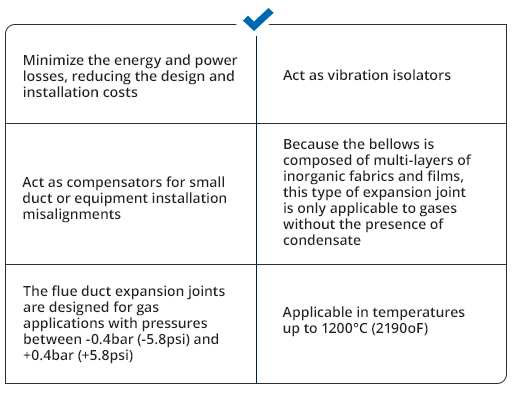

It is critical to understand that a flue duct expansion joint is a highly specialized product that needs special attention to the design, installation and operation phases for a correct and safe performance.

In most flue duct expansion joints applications, a careful analysis of the system is required prior, in order to determine the type, materials of construction needed and other required components.

Following are the main variables that should be considered regarding flue duct expansion joint design and manufacturing.

The Bellows is composed of multi-layers of inorganic fabrics, fluoropolymer layers externally impregnated with silicon or PTFE. This composition provides strength, chemical resistance, temperature resistance and flexibility to absorb movements. In some bellows that work at high temperature and have a combination of fabric and thick insulation multi-layers, a wire mesh can be used to strengthen the bellows, maintaining their integrity.

Metallic frames are necessary to connect the bellows to the ducts. Properly designed, the frames can be directly welded to the ducts, dispensing with the use of additional flanges and enabling cost savings. Their geometry is a preponderant factor to the proper bellows performance and future maintenance.

The inner sleeves are designed to protect the bellows and insulation pillow from turbulent flow. The inner sleeves are also used to control of accumulation of particulate materials in the frame cavity, besides very efficient to maintain the thermal gradient between the media and the bellows. As a basic rule, they should be adopted when the flow velocity exceeds 10m/s (32.8ft/s).

The insulation pillow must be used whenever the media has solid particulates, to avoid these materials accumulating in the metallic frame cavity. If particulate matter is allowed to accumulate, the expansion joint will lose flexibility or, in certain cases, these particulates can combust, reaching high temperatures. Also, on exhaust turbine ducts or large draft fans, it is necessary to fill out the cavity to avoid any pressure variations (flutter), on the start-up, which may cause premature rupture of the bellows. In expansion joints that work at high temperature, the insulation pillow is used as additional insulation, allowing applications up to 1200ºC (2190ºF).

It is manufactured using fabrics with high thermal insulation properties, to protect the bellows from heat transfer through the metallic frame.

Positioned on the bellows external surface, it connects the bellows to the metallic frame and provides the system sealing when in operation. Its width and thickness should be properly designed to fulfill this function, considering the correct bolt spacing. It has rounded edges to prevent damage to the bellows.

Besides the bellows having its own sealing surface, it is necessary in some situations to incorporate additional sealing to compensate for irregularities, especially with thin bellows.

Usually present on systems that work at high temperatures, the external insulation must not overlap the bellow at the risk of preventing the heat exchange between the bellows and the environment, causing irreversible deterioration of the fabric.

TEADIT® recommends the use of welded connections (as stated on item Metallic Frame), but there are the flange connection options.

Sales: Phone (281) 476-3900 – Fax (281) 476-3999 – TOLL FREE: 800-999-0198

E-mail: sales@teadit.com